Why is e-Waste problematic?

The equipment disposed of in bulky waste containers is mostly recycled in developing countries. However, despite the separation of e.g. flame-retardant plastics, portable batteries and capacitors, a considerable amount of unusable electronics is still melted down.

Cost efficiency and sustainability

For us, unbeatable value for money, top quality and sustainability is absolutely no contradiction. Each remanufactured and re-commissioned unit saves 10 to 20 kg of CO2 emissions and up to 10 kg of raw material extraction compared to new production. In addition, the problematic raw materials such as 'rare earth metals' remain directly in the cycle and do not even have to be recycled. This saves the limited resources of our environment.

The reprocessing of electronics is much more environmentally friendly than the recycling of individual raw materials.

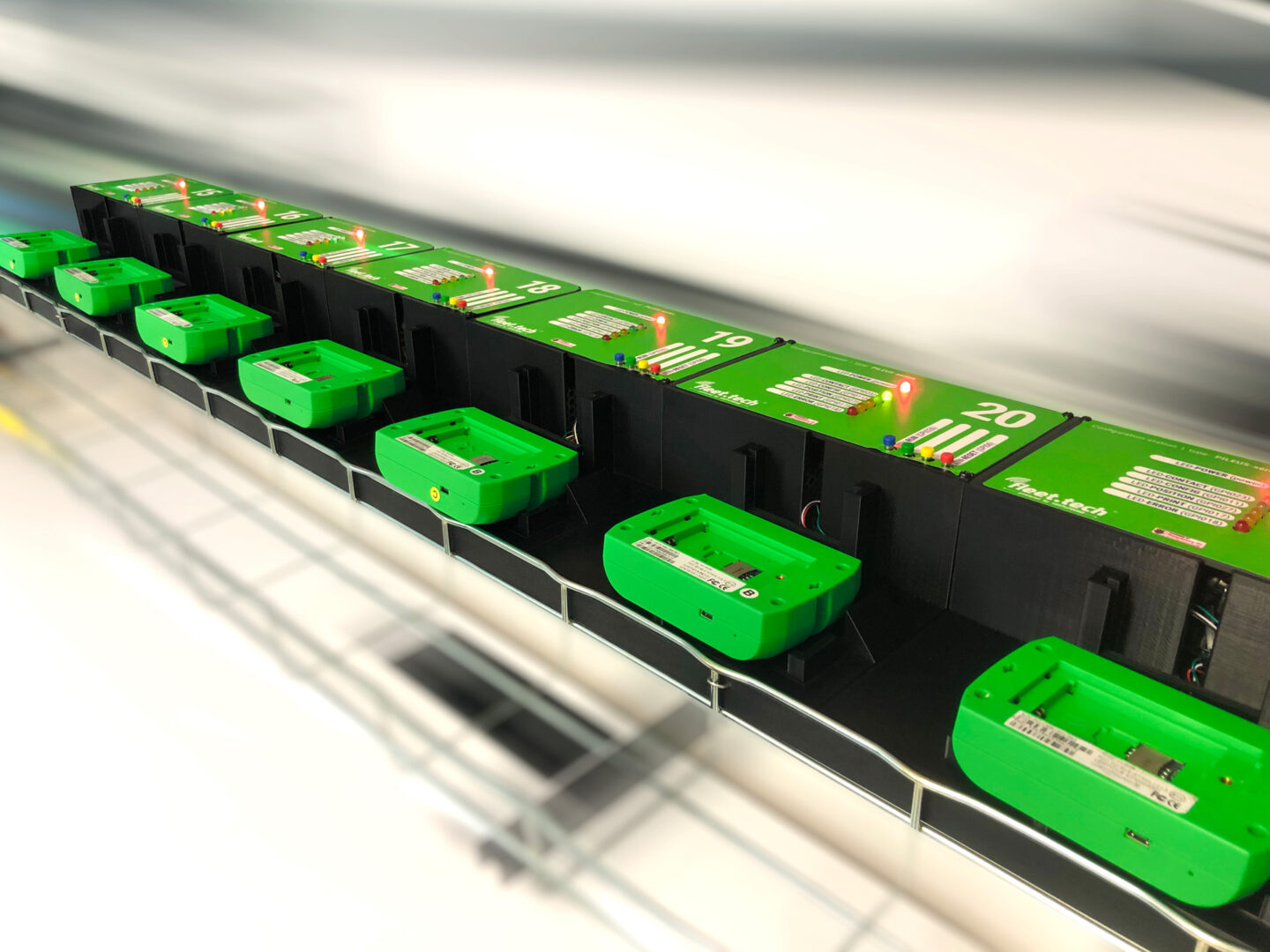

Customers can return end devices to us if they are replaced due to a reduction of the vehicle fleet or by upgrading with devices with an extended range of functions. In a multi-stage process, these devices are then analysed, restored and extensively tested before being delivered again.

What we are particularly proud of

Since the end of 2019, well over a thousand devices from the ALTUS, LENTICUS and PILEUS product families have been reused in a systematic process!

Customers who use "ReMade" products benefit from an even better price-performance ratio, with no restrictions in terms of functionality and/or quality of the products.

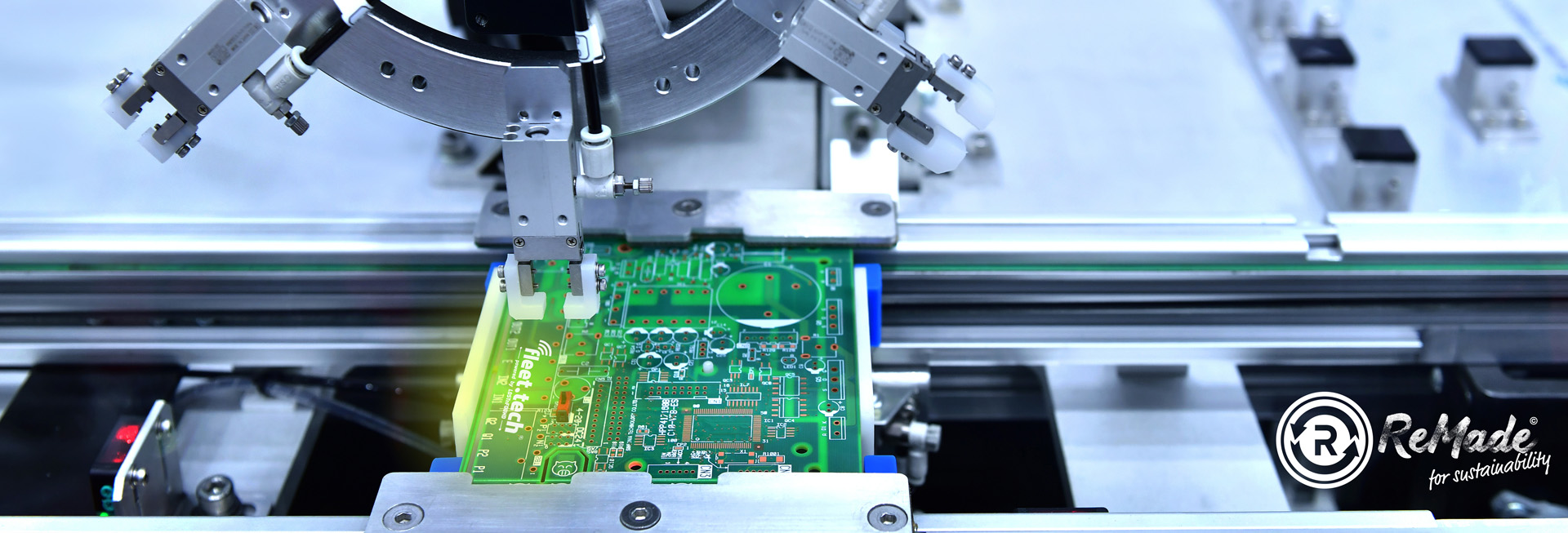

In a first step, the devices are first checked individually, for their technical functions and integrity, disassembled into individual parts and cleaned. Thanks to the modular design of our terminals, up to 18 components such as housing parts, screws, batteries, antennas, cabling, connectors or entire circuit boards can be replaced. Defective and non-repairable individual parts are further disassembled, sorted and handed over to our partners for professional recycling.

In a further step, the devices are loaded with the latest available software update, configured and prepared for the long-term test.

In our fully automated test stations, all devices undergo a multi-stage test and are subjected to extensive functional and performance tests. Important: The same criteria apply for the evaluation of performance as for our new devices. This means that end devices that do not meet the test criteria are consistently sorted out.

We keep an extensive spare parts warehouse available for required additional and replacement components. In this step, the thoroughly tested end devices are completed with the corresponding accessories, packed in an environmentally friendly manner and marked with the "ReMade" label.

With the dispatch of the "ReMade products" we hand over as good as new end devices to a second destination.

Pre-history

However, "ReMade" has a history, and so the prevention of e-waste begins with the production of our high-tech products. Already during the development of our end devices, we make sure that high-quality components and production techniques are used wherever possible. Basically, we prefer the modular, somewhat more elaborate construction to an integral design. With the "ReMade" label from fleet.tech by LOSTnFOUND, we subsequently support the efforts to achieve a close cycle management with the aim of reducing the downcycling of secondary raw materials.

As a responsible medium-sized company, we also continuously and consistently analyse the CO2 footprint of all our products and processes. Our data centres have been operated climate-neutrally since 2014 and with our tools for climate-neutral transport, we help our customers to better understand their own footprint.

For us, sustainability is not just a promise to future generations, but a way of thinking that is lived out in practice.

Contact

Information

AGB