Climate change concerns all players in the economy, not least the transport sector. The CO2 emissions of a transport vehicle over its entire service life depend on fuel consumption, mileage and many other factors. In the transport industry it is still unusual to compensate the CO2 emissions of the vehicles. So far, there has been a lack of practicable solutions for the simple, reliable, recording and calculation of greenhouse gas emissions from transport vehicles - for both light and heavy commercial vehicles.

The fleet.tech CO2 balance thus provides companies with a novel instrument for recording the amount of CO2 greenhouse gases produced by vehicles. The so-called fleet.tech dashboard not only gives a fleet manager an overview of the efficiency and safety behaviour of his vehicle fleet, but also shows the CO2 emissions in tonnes for each vehicle. As a result, these emissions can be voluntarily offset via the myclimate foundation.

The transport and logistics industry is essential for our daily lives and our economy. The associated CO2 footprint can now be offset and industry can make its contribution to achieving global climate targets. We are therefore pleased that the design of the fleet.tech solution also took the issue of CO2 emissions into account. The CO2 data and the possibility of compensation by us help fleet operators to act more climate-friendly immediately and without complications

Stephen Neff, CEO of the myclimate foundation

The methodology for calculating the life cycle assessment of a vehicle registered with fleet.tech is based on the so-called "life cycle" approach. This means that in calculating the CO2 footprint of a vehicle, the processes and their environmental impact are taken into account proportionately from the beginning ("manufacture") to the end ("disposal") of a vehicle. It does not matter whether the vehicles in question are light or heavy commercial vehicles, as the system has been designed in such a way that a wide variety of vehicle types can already be retrieved from a database of more than 30,000 vehicles.

The methodology for calculating the life cycle assessment of a vehicle registered with fleet.tech is based on the so-called "life cycle" approach. This means that in calculating the CO2 footprint of a vehicle, the processes and their environmental impact are taken into account proportionately from the beginning ("manufacture") to the end ("disposal") of a vehicle. It does not matter whether the vehicles in question are light or heavy commercial vehicles, as the system has been designed in such a way that a wide variety of vehicle types can already be retrieved from a database of more than 30,000 vehicles.

For each vehicle, the vehicle fleet can be recorded in detail with details such as manufacturer, model, exhaust emission standard, vehicle year of construction, etc. The fleet.tech system then records all journeys using GPS and other consumption data and automatically calculates the emissions and the corresponding CO2 compensation amount. Whether a carrier wants to pass on the compensation costs to his customers or not remains his decision.

The following video shows how the fleet.tech system looks and works in detail.

Get your individual offer now!

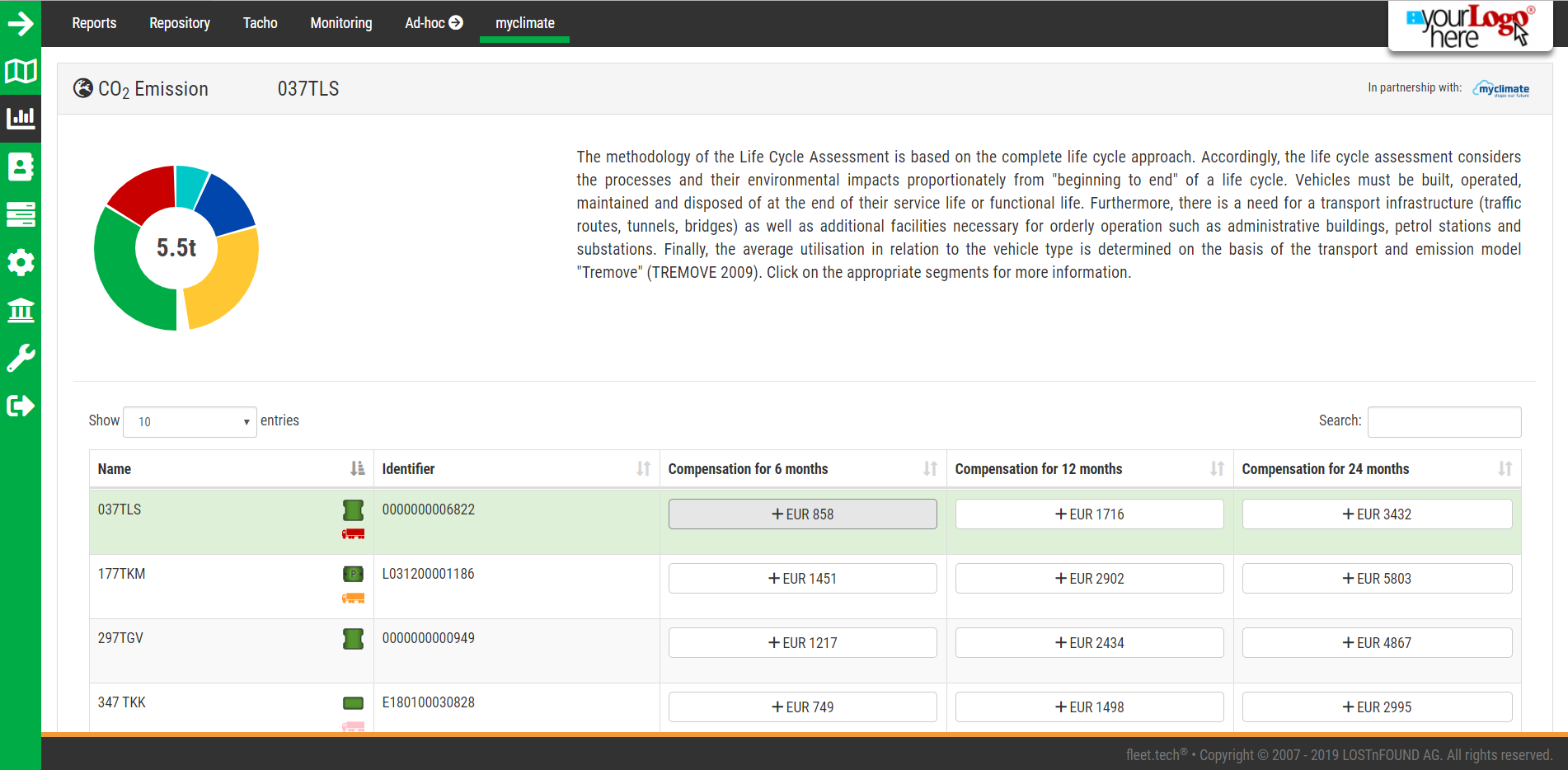

The methodology of the Life Cycle Assessment is based on the complete life cycle approach. Accordingly, the life cycle assessment considers the processes and their environmental impacts proportionately from "beginning to end" of a life cycle. Vehicles must be built, operated, maintained and disposed of at the end of their service life or functional life. Furthermore, there is a need for a transport infrastructure (traffic routes, tunnels, bridges) as well as additional facilities necessary for orderly operation such as administrative buildings, petrol stations and substations. Finally, the average utilisation in relation to the vehicle type is determined on the basis of the transport and emission model "Tremove" (TREMOVE 2009).

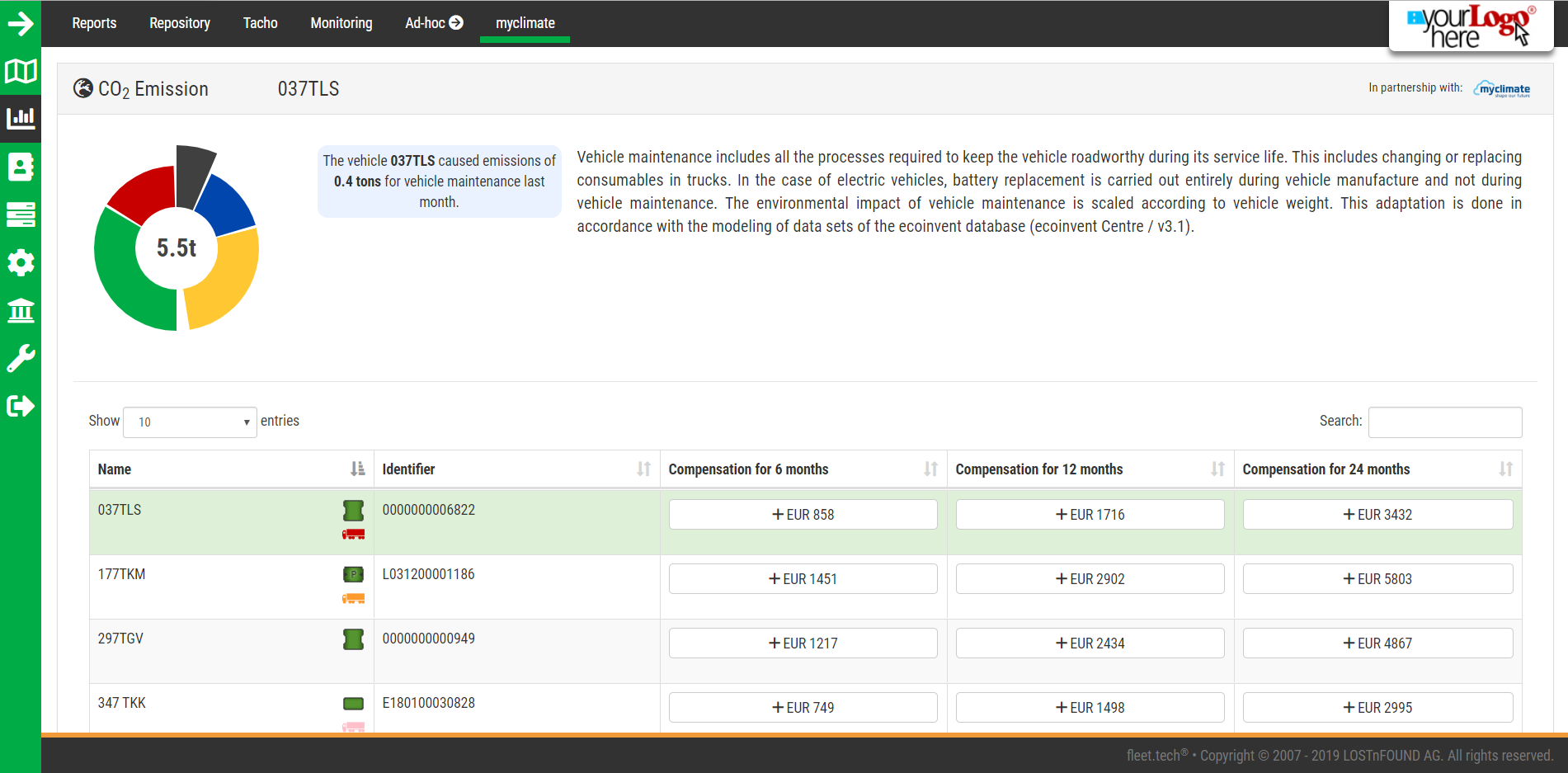

Vehicle maintenance includes all the processes required to keep the vehicle roadworthy during its service life. This includes changing or replacing consumables in trucks. In the case of electric vehicles, battery replacement is carried out entirely during vehicle manufacture and not during vehicle maintenance. The environmental impact of vehicle maintenance is scaled according to vehicle weight. This adaptation is done in accordance with the modeling of data sets of the ecoinvent database (ecoinvent Centre / v3.1).

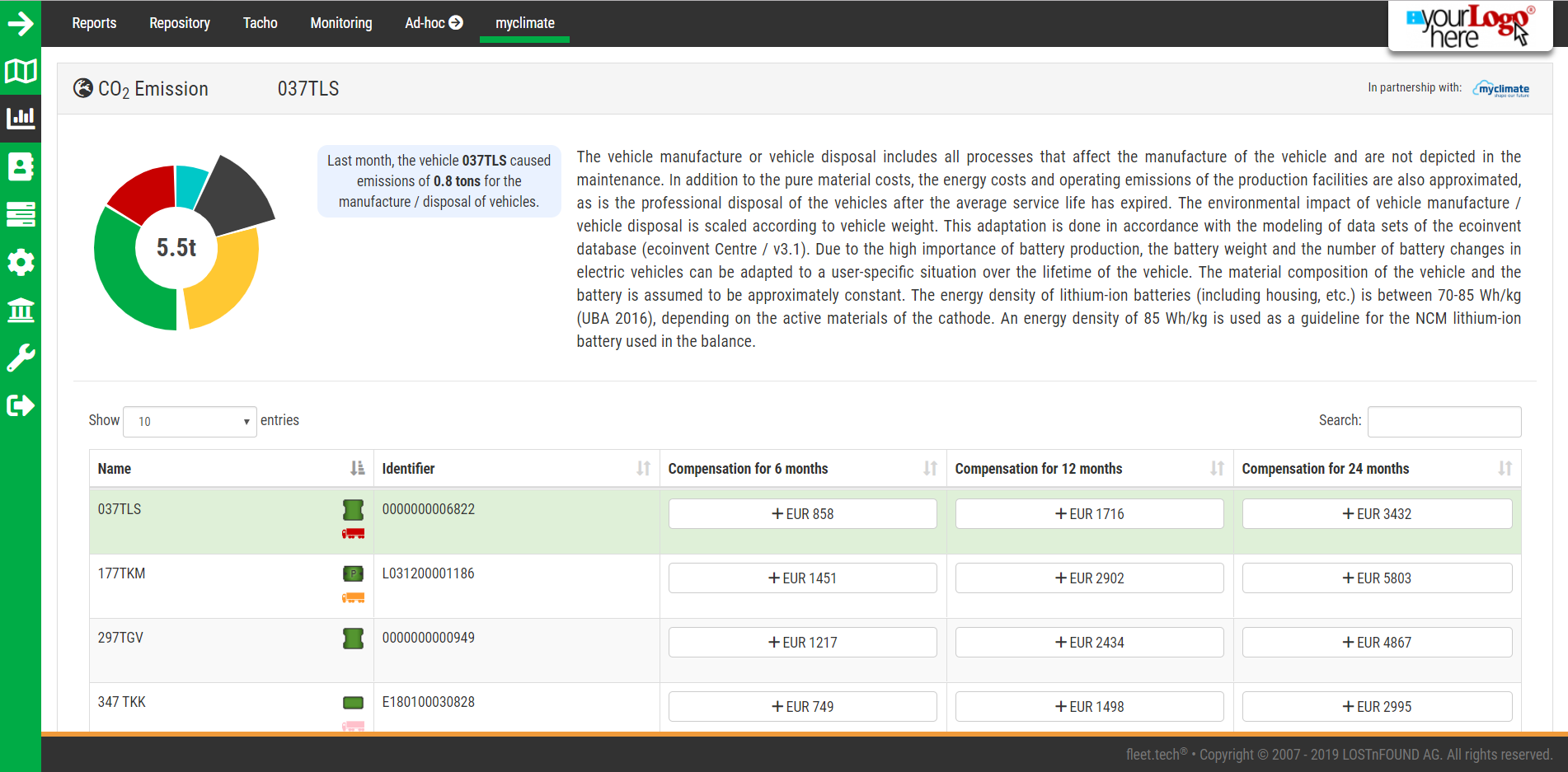

The vehicle manufacture or vehicle disposal includes all processes that affect the manufacture of the vehicle and are not depicted in the maintenance. In addition to the pure material costs, the energy costs and operating emissions of the production facilities are also approximated, as is the professional disposal of the vehicles after the average service life has expired. The environmental impact of vehicle manufacture / vehicle disposal is scaled according to vehicle weight. This adaptation is done in accordance with the modeling of data sets of the ecoinvent database (ecoinvent Centre / v3.1). Due to the high importance of battery production, the battery weight and the number of battery changes in electric vehicles can be adapted to a user-specific situation over the lifetime of the vehicle. The material composition of the vehicle and the battery is assumed to be approximately constant. The energy density of lithium-ion batteries (including housing, etc.) is between 70-85 Wh/kg (UBA 2016), depending on the active materials of the cathode. An energy density of 85 Wh/kg is used as a guideline for the NCM lithium-ion battery used in the balance.

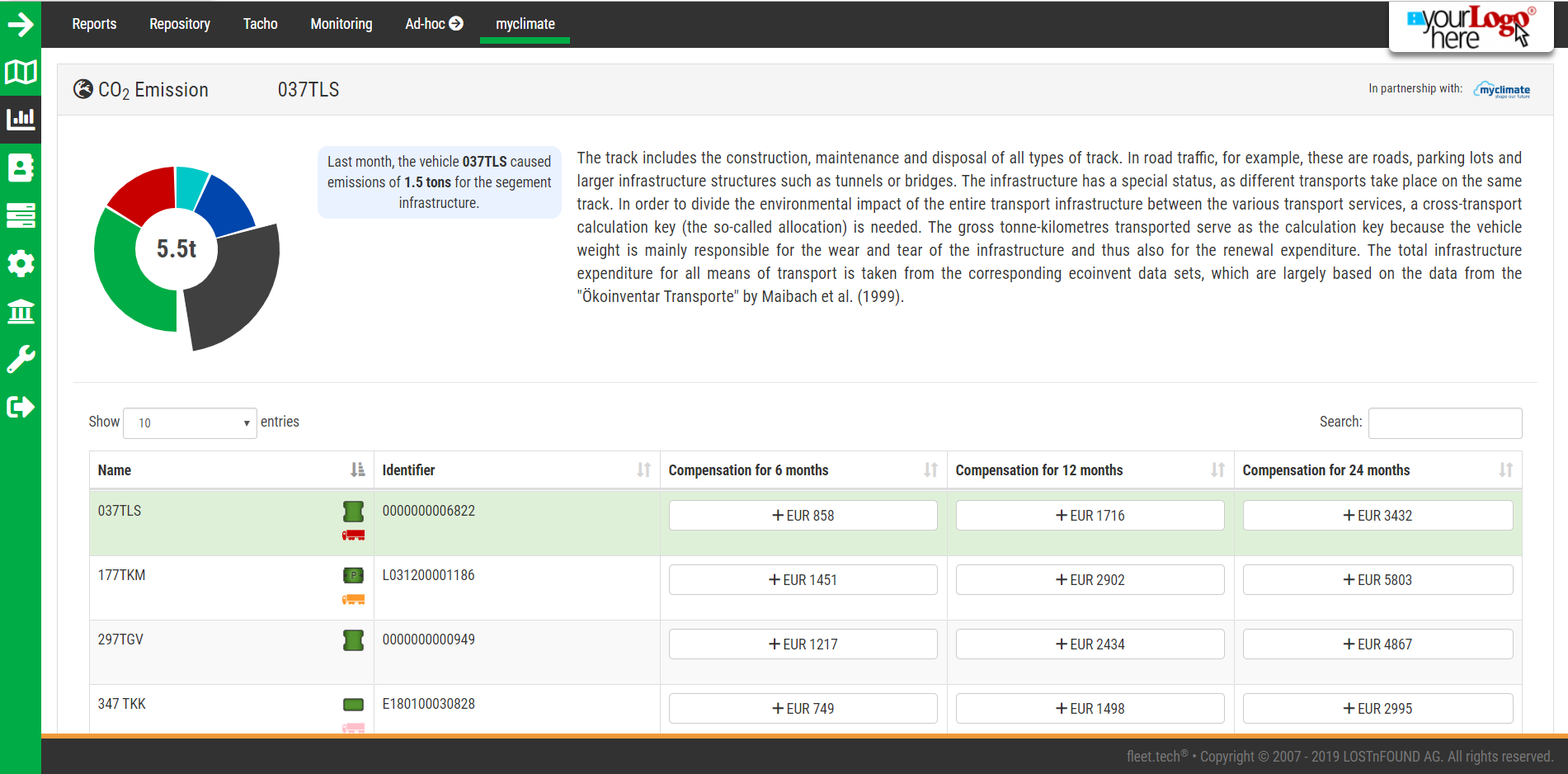

The track includes the construction, maintenance and disposal of all types of track. In road traffic, for example, these are roads, parking lots and larger infrastructure structures such as tunnels or bridges. The infrastructure has a special status, as different transports take place on the same track. In order to divide the environmental impact of the entire transport infrastructure between the various transport services, a cross-transport calculation key (the so-called allocation) is needed. The gross tonne-kilometres transported serve as the calculation key because the vehicle weight is mainly responsible for the wear and tear of the infrastructure and thus also for the renewal expenditure. The total infrastructure expenditure for all means of transport is taken from the corresponding ecoinvent data sets, which are largely based on the data from the "Ökoinventar Transporte" by Maibach et al. (1999).

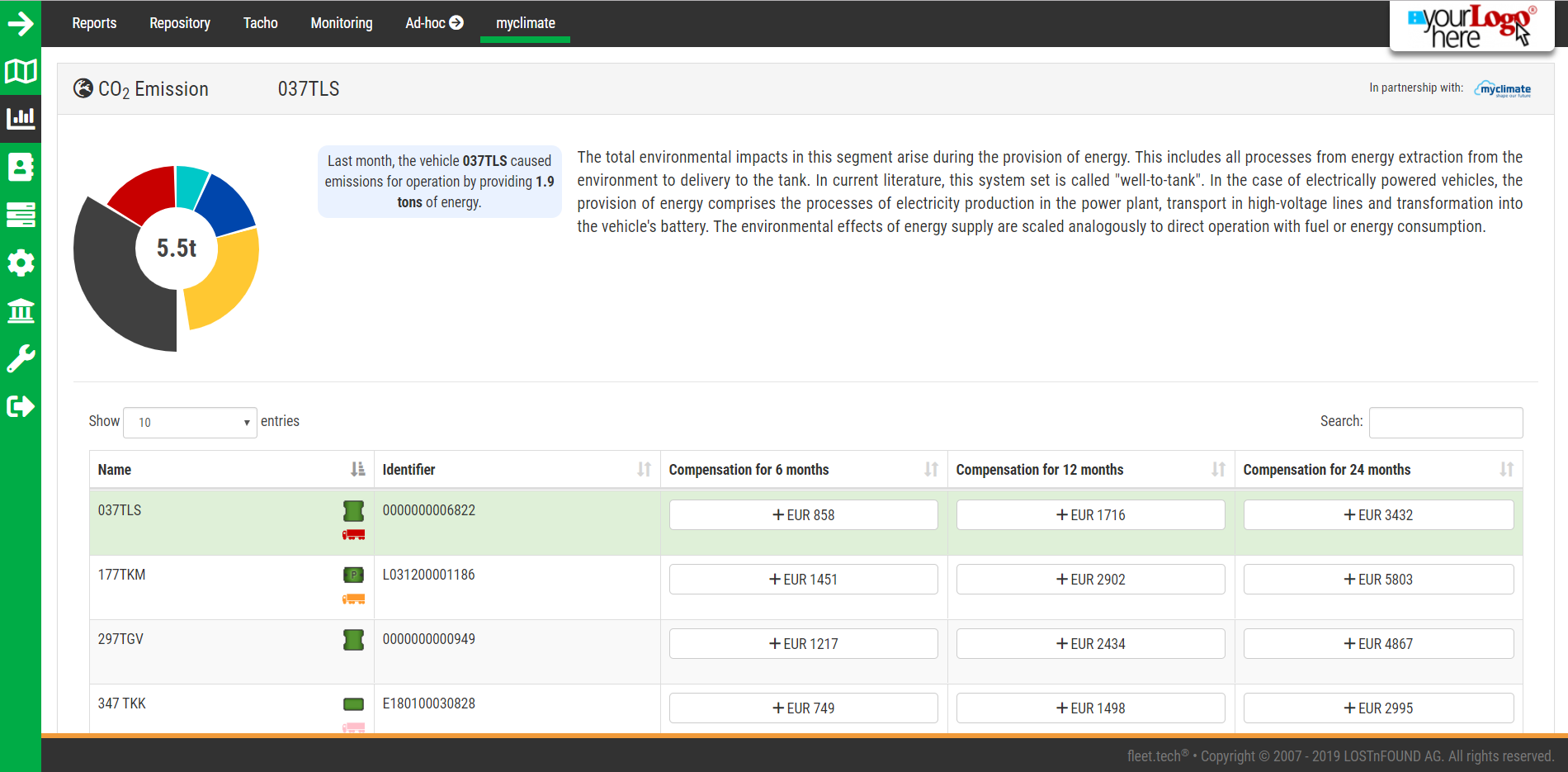

The total environmental impacts in this segment arise during the provision of energy. This includes all processes from energy extraction from the environment to delivery to the tank. In current literature, this system set is called "well-to-tank". In the case of electrically powered vehicles, the provision of energy comprises the processes of electricity production in the power plant, transport in high-voltage lines and transformation into the vehicle's battery. The environmental effects of energy supply are scaled analogously to direct operation with fuel or energy consumption.

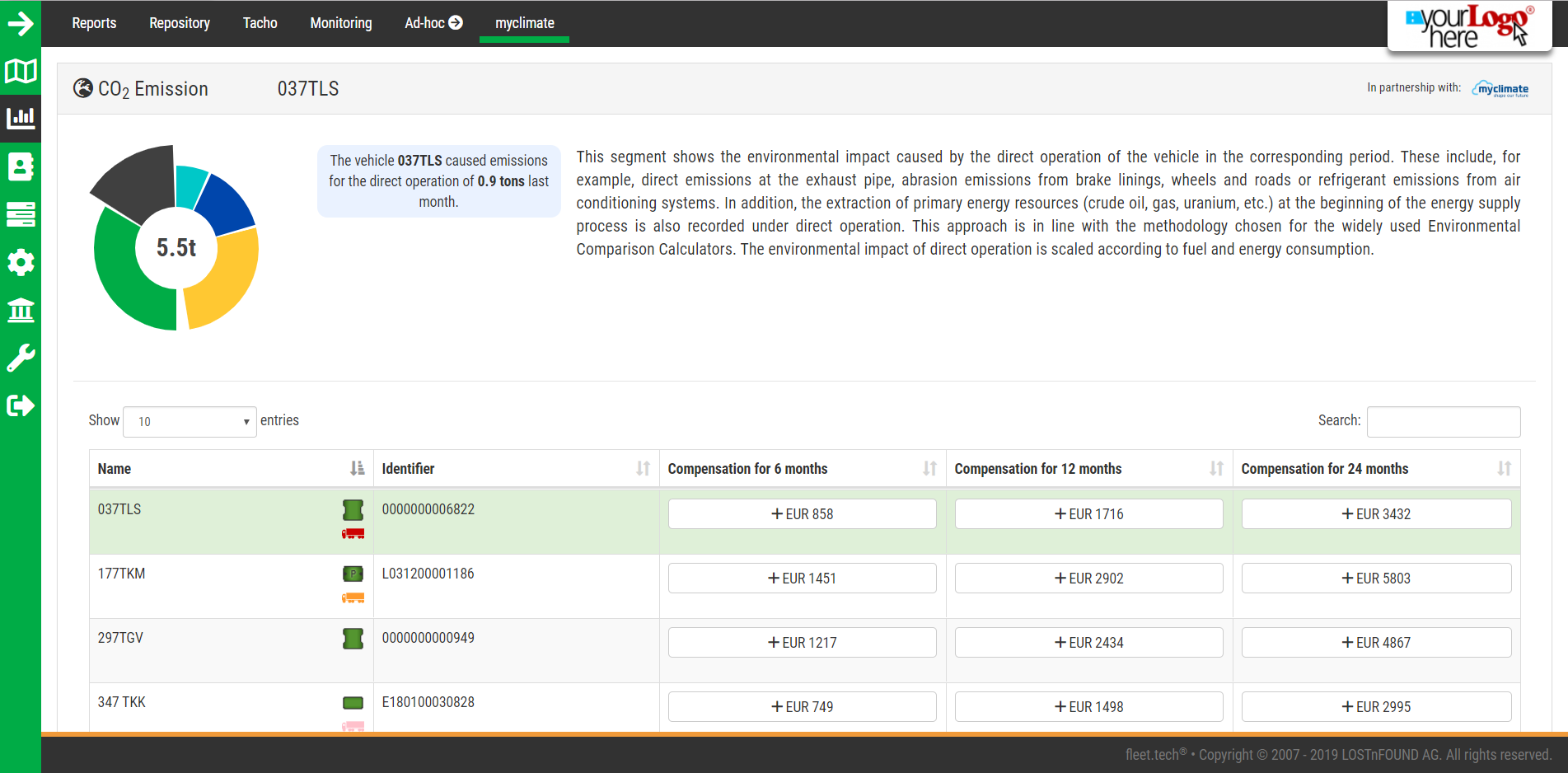

This segment shows the environmental impact caused by the direct operation of the vehicle in the corresponding period. These include, for example, direct emissions at the exhaust pipe, abrasion emissions from brake linings, wheels and roads or refrigerant emissions from air conditioning systems. In addition, the extraction of primary energy resources (crude oil, gas, uranium, etc.) at the beginning of the energy supply process is also recorded under direct operation. This approach is in line with the methodology chosen for the widely used Environmental Comparison Calculators. The environmental impact of direct operation is scaled according to fuel and energy consumption.

Every fleet. tech customer can voluntarily offset the amount of CO2 produced within 6, 12 or 24 months per vehicle or part of the fleet with an amount of money - with just one mouse click. The fleet. tech system automatically produces an invoice and an individual myclimate compensation certificate.

On request, vehicle stickers can also be provided for advertising purposes with a reference to CO2 compensation. This makes it clear to third parties that the vehicle in question is "climate-neutral".

100 percent of the money received from customers for CO2 offsetting goes to the myclimate foundation. The CO2 balances and evaluations we produce are completely free of charge for our customers. With the possibility of uncomplicated CO2 offsetting, we would like to offer our customers a simple tool for further charging for climate-neutral transports.

Daniel Thommen, founder and managing director of the LOSTnFOUND Group and provider of the fleet.tech solution

Get your individual offer now!

Contact

Information

AGB